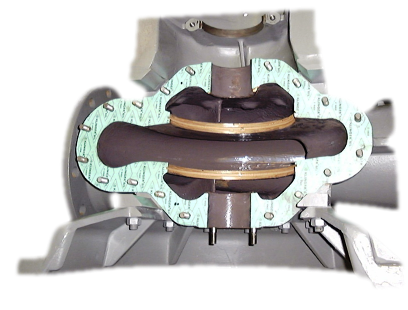

Pump

Repair and repair instead of purchasing new ones.

This relieves the burden on the budget and can also lead to enormous time savings.

We carry out repairs according to your needs, from a simple mechanical overhaul to a complete overhaul with

appropriate surface technology.

Surface technology

- Industrial seawater and chemical resistant protective coating

and polymer repair composites with

excellent properties against corrosion, cavitation and electrolysis

- Flame spraying with wire, powder, oxides and composite

A complete repair to refurbish worn metallic units and components includes several work processes:

- Sandblasting

- Modeling and building up damaged or severely worn contours and

shapes to the original design with special materials and processes

- Closing pitting areas and cracks

- Complete surface coating - pre-coating

- Complete protective coating

- Replacement of seals, bearings and small parts

- Concentricity test for rotating components

- Replacement of non-repairable mechanical functional parts

- Mechanical function test

- Protective coating

- Pressure test

VOLUTE CASING / COVER / IMPELLER / SHAFT / CASING WEAR RING / BEARING SEAT

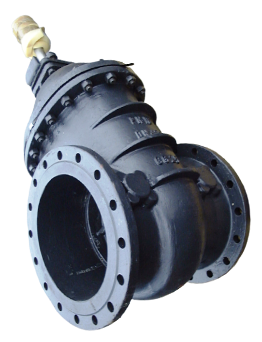

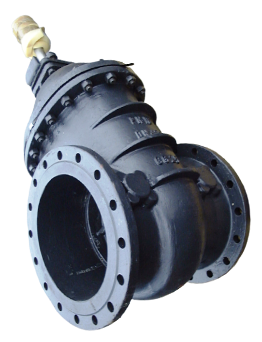

Gate Valve

Repair and repair instead of purchasing new ones.

This relieves the burden on the budget and can also lead to enormous time savings.

We carry out repairs according to your needs, from a simple mechanical overhaul to a complete overhaul with

appropriate surface technology.

Surface technology

- Industrial seawater and chemical resistant protective coating

and polymer repair composites with

excellent properties against corrosion, cavitation and electrolysis

- Flame spraying with wire, powder, oxides and composite

A complete repair to refurbish worn metallic units and components includes several work processes:

- Sandblasting

- Modeling and building up damaged or severely worn contours and

shapes to the original design with special materials and processes

- Closing pitting areas and cracks

- Complete surface coating - pre-coating

- Complete protective coating

- Replacement of seals, bearings and small parts

- Concentricity test for rotating components

- Replacement of non-repairable mechanical functional parts

- Mechanical function test

- Protective coating

- Pressure test

CASING / SLIDE PLATE / FLAP / BEARING / BEARING SEAT / SHAFT / SEAL

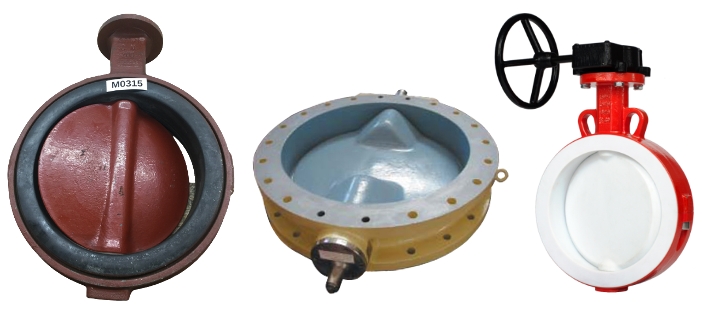

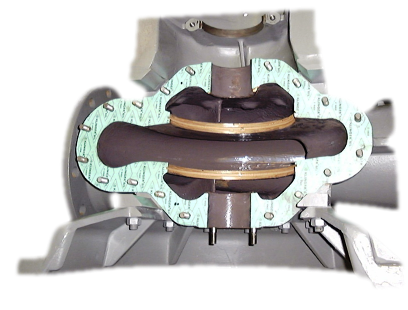

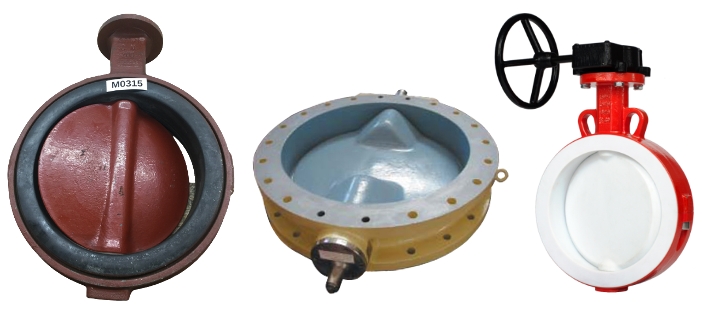

Butterfly Valve

Repair and repair instead of purchasing new ones.

This relieves the burden on the budget and can also lead to enormous time savings.

We carry out repairs according to your needs, from a simple mechanical overhaul to a complete overhaul with

appropriate surface technology.

Surface technology

- Industrial seawater and chemical resistant protective coating

and polymer repair composites with

excellent properties against corrosion, cavitation and electrolysis

- Flame spraying with wire, powder, oxides and composite

A complete repair to refurbish worn metallic units and components includes several work processes:

- Sandblasting

- Modeling and building up damaged or severely worn contours and

shapes to the original design with special materials and processes

- Closing pitting areas and cracks

- Complete surface coating - pre-coating

- Complete protective coating

- Replacement of seals, bearings and small parts

- Concentricity test for rotating components

- Replacement of non-repairable mechanical functional parts

- Mechanical function test

- Protective coating

- Pressure test

BODY / DISC / BODY LINER / BEARING SEAT / BEARING / SHAFT / SEAL

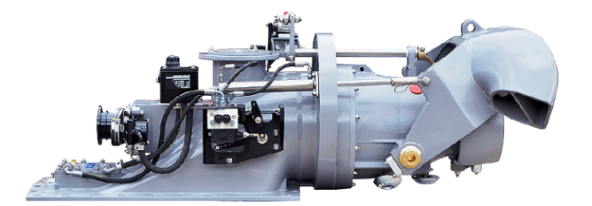

Bow Thruster

Repair and repair instead of purchasing new ones.

This relieves the burden on the budget and can also lead to enormous time savings.

We carry out repairs according to your needs, from a simple mechanical overhaul to a complete overhaul with

appropriate surface technology.

Surface technology

- Industrial seawater and chemical resistant protective coating

and polymer repair composites with

excellent properties against corrosion, cavitation and electrolysis

- Flame spraying with wire, powder, oxides and composite

A complete repair to refurbish worn metallic units and components includes several work processes:

- Sandblasting

- Modeling and building up damaged or severely worn contours and

shapes to the original design with special materials and processes

- Closing pitting areas and cracks

- Complete surface coating - pre-coating

- Complete protective coating

- Replacement of seals, bearings and small parts

- Concentricity test for rotating components

- Replacement of non-repairable mechanical functional parts

- Mechanical function test

- Protective coating

- Pressure test

VOLUTE CASING / COVER / BEARING / BEARING SEAT / SHAFT / CASING RING

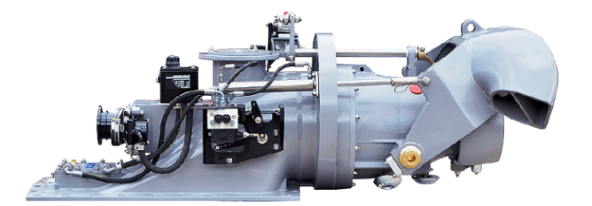

Jet Drive

Repair and repair instead of purchasing new ones.

This relieves the burden on the budget and can also lead to enormous time savings.

We carry out repairs according to your needs, from a simple mechanical overhaul to a complete overhaul with

appropriate surface technology.

Surface technology

- Industrial seawater and chemical resistant protective coating

and polymer repair composites with

excellent properties against corrosion, cavitation and electrolysis

- Flame spraying with wire, powder, oxides and composite

A complete repair to refurbish worn metallic units and components includes several work processes:

- Sandblasting

- Modeling and building up damaged or severely worn contours and

shapes to the original design with special materials and processes

- Closing pitting areas and cracks

- Complete surface coating - pre-coating

- Complete protective coating

- Replacement of seals, bearings and small parts

- Concentricity test for rotating components

- Replacement of non-repairable mechanical functional parts

- Mechanical function test

- Protective coating

- Pressure test

INTAKE HOUSING / DIFFUSER / IMPELLER / WEAR RING / NOZZLE / DEFLECTOR

Injection

Repair and repair instead of purchasing new ones. From conventional injection technology to the

state-of-the-art common rail injection system

OVERHAUL & MODIFICATION

You can also expect the longest durability and the best reliability from high-quality materials. With

modern

test benches and experienced diesel specialists

We offer:

- Overhaul and modification from fuel pump to fuel valve

- For large 2- and 4-stroke diesel engines from all engine

manufacturers

- Damage wear analysis

- Individual and series production of machine components

- Measuring: Quality control at every step of production

- Compliance with the prescribed parameters

- Corrosion-resistant packaging

A thorough inspection of your fuel injectors can help you identify potential problems before they cause

major

damage.

BOSCH / DENSO / DELPHI / MARELLI / EDELBROCK / KEIHIN / WOODWARD

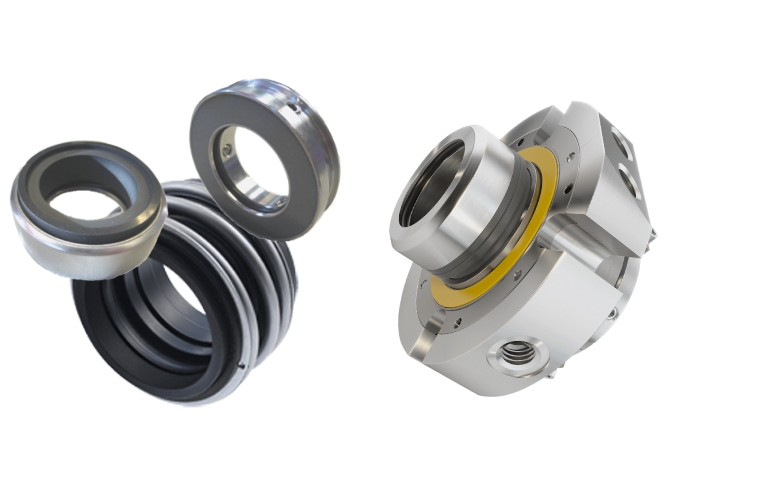

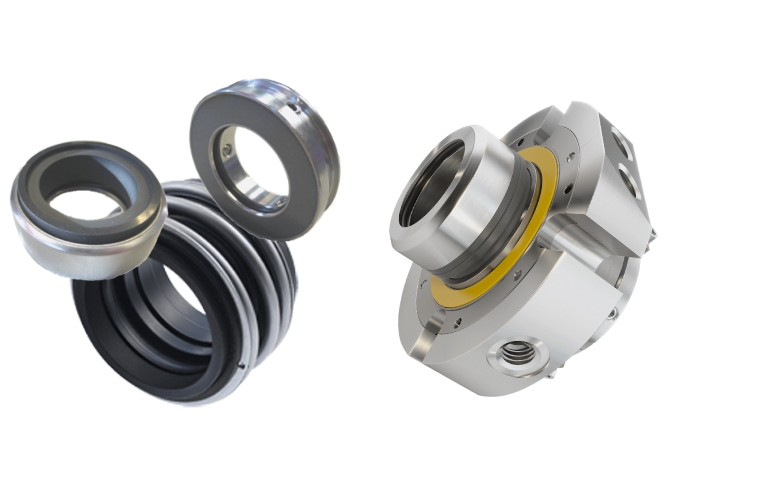

Mechanical Seal

Repair and repair instead of purchasing new ones

REPAIR & OVERHAUL

From simple spiral spring and bellows seals to cartridge seals of all sizes and manufacturers.

Mechanical seals are subject to a wide variety of wear factors. If your mechanical seal is damaged, we will

check whether repairs are economically worthwhile.

For mechanical seals with a high value and if the requirements of the corresponding components allow it,

there is the possibility of professional, high-quality and quality-tested reconditioning by qualified

employees with modern test benches, which means significant savings can be achieved in the maintenance of

your

system.

We carry out the workflows as follows:

- Checking the seal

- Checking the individual components

- Damage analysis for operating conditions

- Offer to modify if required

- Reconditioning of reusable parts

- Lapping and polishing the sliding surfaces

- Replacing non-repairable parts with high quality materials

- Pressure test

SPIRAL SPRING / RUBBER BELLOW / METAL BELLOW / CARTRIDGE / SPLIT

Seating Systems

Repair and repair instead of purchasing new ones

REPAIR & OVERHAUL

Daily stress on the upholstery and mechanical assemblies often leads to premature wear, depending on the

quality. The seating comfort decreases or the upholstery material has holes and tears, the mechanics are

stuck, so the question often arises: repair or replace?

Basically, almost any fabric is suitable for upholstery, but not suitable for sitting on. Upholstery

fabrics

have a minimum of 20,000 abrasion cycles (Martindale test). If you're looking for durability, it's better to

choose one with 50,000 cycles. The composition of the underpad and upholstery as well as the appropriate

choice of spring types and systems and their materials are also important for a long service life.

We carry out repairs according to your needs. Sustainable, precise with years of experience.

Upholstery and saddlery work from simple fabric coverings to high-quality leather.

Mechanical work from the simple spring suspension and adjustment mechanisms to the stable lifting column and

shock-resistant base.

Work often carried out on:

- Headrest

- Armrest

- Adjustment lever

- Seat cushion

- Backrest

- Adapter plate

- Suspension

- Lifting column

- Slipcovers

CLEEMANN / GERPOL / HI-SEA / ISRI / LUND / NORSAP / SEAPOST / SEIMI / VETUS

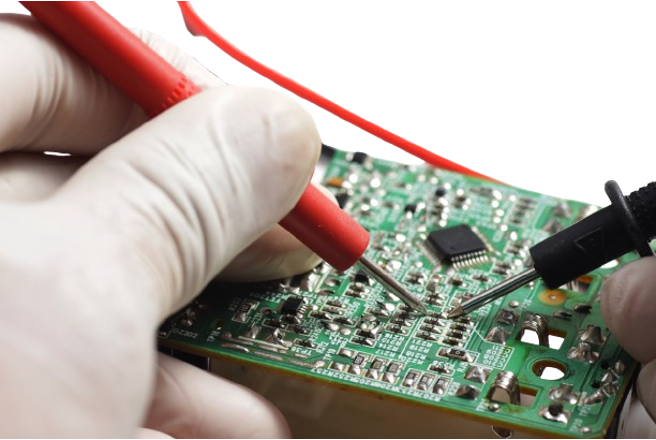

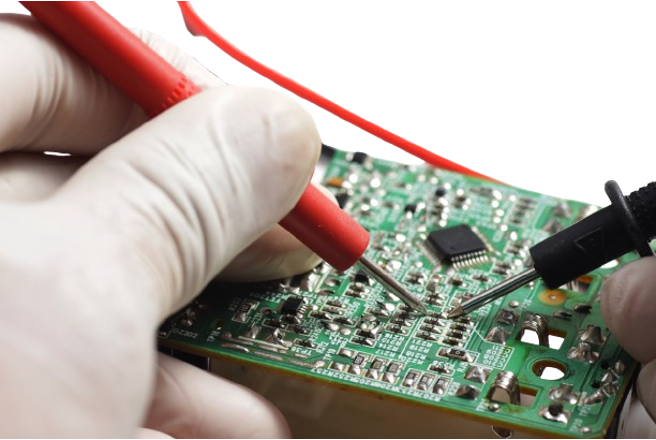

Electronic components

Repair and repair instead of purchasing new ones

ELECTRONIC TROUBLESHOOTING AND REPAIR

We diagnose, troubleshoot and repair any device that includes one or more electronic cards, regardless of

make or model.

In the event of serious failures, obsolescence or critical electronic systems, we can offer equivalent

replacement modules or redesign the electronic board if possible.

With qualified employees and many years of experience with all generations of analog and digital devices,

we

offer repairs and troubleshooting without circuit diagrams and systematically follow strict methods to

ensure

impeccable service quality.

- Problem discussion with customers

- Analysis and diagnosis of errors

- Repair solutions

- Prepare for troubleshooting

- Procurement of components from electronic components inventory

or

from partners

- Electronic rework, CMS, BGA

FOR ALL ELECTRONIC CARDS / ALL BRANDS AND MODELS / ANALYSIS AND DIAGNOSIS OF ERRORS /

REPAIR SOLUTIONS / PREPARE FOR TROUBLESHOOTING / PROCUREMENT OF COMPONENTS / ELECTRONIC REWORK CMS BGA