DIESEL ENGINES

Marine diesel engines are available in almost all sizes and performance classes. The

largest and most powerful engines are usually slow-speed two-stroke engines; Four-

stroke engines are built in large and medium performance classes as medium-speed

engines, small ship diesel engines are often high-speed engines.

Like all diesel engines, marine diesel engines are in principle suitable for multiple

fuels and can be operated with a large number of different fuels. Commercially

available DIN EN 590 diesel fuel is relatively expensive and only plays a role in small

four-stroke engines; larger four-stroke engines and two-stroke engines are usually

operated with gas oil, heavy oil (HFO) or, more recently, with liquefied natural gas

(LNG). Orimulsion was also used as fuel until the end of 2006. The term diesel refers

to the work process, which, according to definition, is characterized by the intake of

air, its compression with associated heating and the self-ignition of the fuel after its

injection and combustion with a diffusion flame.

The requirements for operational safety and reliability are very high. The failure of a

ship's propulsion system can have devastating consequences. Great importance is

placed on quality and a long service life in order to minimize operating costs in the

long term. In addition, repairs or even replacing the machine involve considerable

effort.

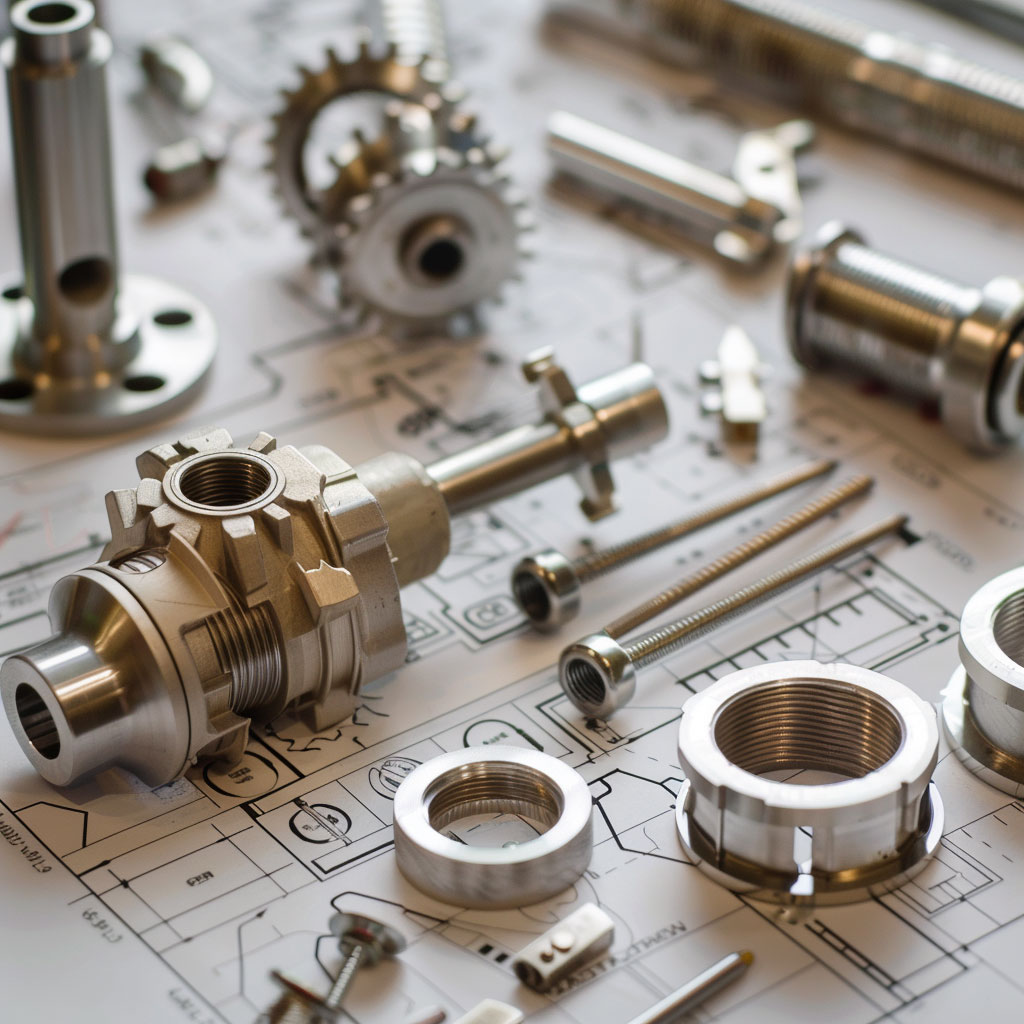

We offer an extensive range of spare parts for high-performance and first-class

marine engines and generators. Over the course of many years we have supplied a

wide variety of spare parts for various marine engines and generators on board

seagoing vessels and to shipyards.

We specialize in the reliable provision and delivery of older and new European and

Asian OEM marine spare parts.

A.B.C. / AKASAKA / CATERPILLAR / CUMMENS / DAIHATSU / DEUTZ-KHD / HYUNDAI HIMSEN / MAK /

MAN B&W / MITSUBISHI / MTU / PIELSTICK / RUSTON / SKL / STORK / SULZER / VOLVO PENTA / WÄRTSILÄ /

WINTERTHUR / YANMAR & some more

Separator & Purifier

The use of separators is particularly important for seagoing vessels with diesel engines. For

the most part, heavy oil is used as fuel. Heavy oil is a residual oil from distillation or cracking

plants in petroleum processing. Therefore, a separator on these vessels is crucial to separate pollutants

and

unrecyclable particles from the oil so that it can be used as fuel.

The operation of a seagoing vessel is therefore heavily dependent on the use of oil

separators, which has also led to an environmental change in the industry. There are two

types of separators/centrifuges: In the cleaner, the centrifuge separates a liquid based on its

density, for example water from oil. Clarifier - when the centrifuge is only used to remove

pollutants and a small amount of water.

In addition, they contribute to the environment and ensure the best oil separation. Because

vessels produce an oil-water mixture that is harmful to sea life, the mixture is separated

using a separator before disposal.

Apart from being a precautionary measure, this law has become an IMO regulation. The

International Maritime Organization and the Marine Environment Protection Committee

implemented it in 2003. It is now known as MEPC 107(49), a document that provides

guidelines for water pollution prevention devices.

According to these guidelines, the oil-water separator must be able to remove 15 ppm of

Type C or highly emulsified oil and other contaminants such as lubricating oil, fuel oil, rust,

sewage, soot and other substances that could be harmful to the Marine environment.

We understand the need and importance of marine separators. That's why we ensure that

our customers' needs are met with the best and highest quality marine separator spare parts.

We are aware of the value of separators as an auxiliary system for the smooth operation of

the entire system. That's why we supply marine separator spare parts from all major brands

in the industry through fast and cost-effective delivery to any location worldwide.

ALFA LAVAL / BALTICA / BETEX / BLOHM & VOSS / DECKMA / DVZ / FAUDI / EKOS /

HAMWORTHY /

HDW-TURBOLO / JOWA / MITSUBISHI KAKOKI KAISHA / MERLIN / MOATTI / NFV MAHLE / PROMAC / RWO /

SAREX / TANAKA / VERLCON / WESTFALIA / YUZHI & many more

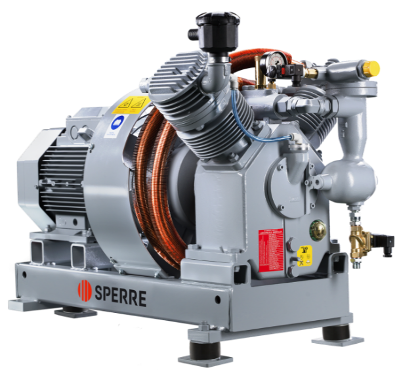

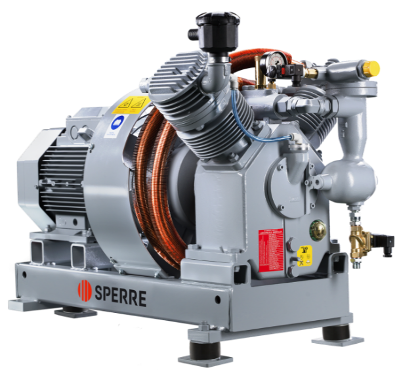

Compressor

Conditions are different at sea than on land, so marine compressors operate slightly

differently than machines used on land.

On seagoing vessels, compressed air serves as a highly effective and easy-to-store

energy source for the starter motors of large diesel engines. Although the air is used

at a pressure of almost 10 bar, the storage form is under higher pressure in order to

make optimal use of the space and still have enough reserve for multiple starts.

Marine compressors are also often used to support the movement of ships and the

control of the main and auxiliary engines.

Many systems and processes in seafaring require compressed air. Emission

monitoring systems for the motors, actuators, control valves and tool air (for

pneumatic chisels, drills and angle grinders) are just a few examples.

Every shipping company knows that sufficient clean water is essential for survival on

seagoing vessels. Marine compressors play a critical role in pressurizing the

hydrophores to maintain this fresh water supply and distributing the water from the

hydrophores to consumers in the vessel.

Sewage systems on board seagoing vessels are supplied with compressed air and

the marine compressors support essential processes in the sewage treatment plant

on board.

Air compressors are very important for supplying safety devices on seagoing vessels,

such as the signal horns! In an emergency, the compressors also power the fire

water pumps that pump seawater and the engines that move lifeboats should the

need arise.

We offer high-quality marine compressor spare parts from leading manufacturers

worldwide.

ALUP / ATLAS COPCO / BAUER / BITZER / BOCK / CEGIELSKI / COLDITZ / DENO / ERVOR / FIAC /

GARDNER DENVER / HAMWORTHY / HANSHIN / HATLAPA / INGERSOLL / JOWA / MATSUBARA /

RIETSCHLE / SABROE / SAUER & SOHN / SPERRE / TAMROTOR / TANABE / TEIKOKU & many more

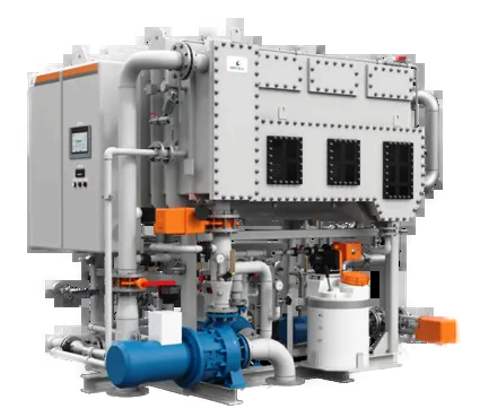

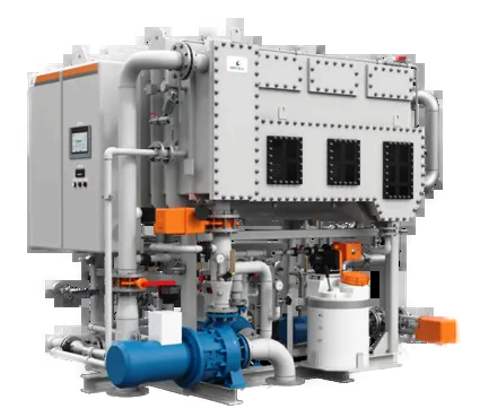

Evaporator

The fresh water generator is the water treatment system on board seagoing vessels.

Technical fresh water is produced from seawater through single-stage distillation; the energy

required usually comes from the cooling water of the engines, less often from the steam

system. Further treatment of the water achieves drinking water quality. This makes it

possible for ships to spend long periods at sea without having to store fresh water. Technical

fresh water is for example used in the steam system to replace feed water losses.

The “cold” seawater first flows through the condenser, which liquefies the water vapor again.

This causes the temperature of the lake water to rise. A portion is then fed into the

evaporator area so that a constant supply of the evaporated water is ensured. The other part

is used as a motive medium for the brine/vacuum pump before it is put overboard again.

The energy for boiling the seawater usually comes from the high-temperature circuit of the

(engine) cooling water that flows through the evaporator. The resulting water vapor is passed

through the droplet separator, which retains salty water drops from the condenser that have

been carried along by the steam flow.

Finally, the steam is liquefied in the condenser and the resulting fresh water is cooled. The

fresh water pump pumps the condensate out of the system and conveys it to the desired

tank. At the exit of the system, a check is made to see whether the salt content is within the

desired limit. An automatic control system intervenes in the process and, if necessary, stops

the system if the salt content increases.

The continuous reduction of seawater in the evaporator leads to a constantly increasing salt

concentration in the liquid to be evaporated. In order to prevent failures in the system, slightly

more seawater is fed into the evaporator than is actually evaporated. The overflowing brine

collects at the bottom of the evaporator and is removed to sea via the brine pump.

There is a seawater evaporator on every seagoing ship. Depending on the size of the

system, up to 60 m³ per day is common; for larger water requirements, for example on cruise

ships, multi-stage systems are often operated in parallel.

Continuous maintenance of these systems is essential so that ships can spend long periods

at sea without having to store fresh water and save high costs.

We specialize in the reliable supply and delivery of older and new European and Asian

evaporator spare parts.

AGC / ALFA LAVAL / API / APV / DONGHWA / FISCHER / GEA / HANSUN / HISAKA / HYDAC / ITT /

KAPP

/ MITSUBISHI / MUELLER / POLARIS / SASAKURA / SERCK COMO / SONDEX / STORK / SWEP /

TRANTER / VICARB / VIEX & some more

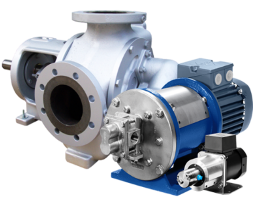

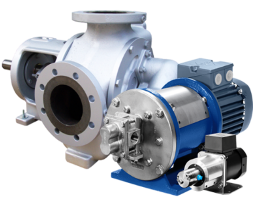

Pump

Pumps for seagoing vessels (ship's pump) are all pumps that comply with the

regulations of the classification societies for shipbuilding.

There are various types of pumps available that are used for different pump

technology:

Centrifugal pumps, Diaphragm pumps, Progessing cavity pumps, Screw pumps,

Submersible pumps, Propeller pumps, Piston pumps, Rotary pumps, Gear pums.

The ship's pump as a centrifugal pump has extremely versatile uses on board. It is

used in the engine room as a boiler feed, condensate and centrifugal pump for sea

and fresh cooling water, in the bow as a transverse jet, in special pump rooms as a

cargo oil, butterworth and ballast pump, and in special functions as a lurcher -,

heeling, trimming, bilge, bilge, fire extinguishing and various service pumps.

Pumps for seawater and fresh cooling water (e.g. the seawater pump) and for fire

extinguishing take their pumped liquid from the sea chests via suction lines. These

are containers arranged on the inside of the ship's side below the waterline with

seaward-facing openings that are covered by inlet rakes. Seawater as a pumping

medium requires appropriate seawater-resistant materials for the pump.

Since large amounts of air often have to be removed from bilge and ballast water

pipes, self-priming pumps are often found on board. These are constantly running

water ring pumps. Separate ventilation devices such as ejectors or central vacuum

systems are also becoming increasingly popular.

Due to the limited space on board, the vertical pump with a directly attached motor

has emerged as the most suitable design for most ship pumps.

On turbine ships with large boiler systems and corresponding condensers, two-flow

centrifugal pumps are used to supply cooling water. Due to the small delivery heads,

longitudinally split propeller pumps are also common.

With our supply of all spare parts for marine pumps, you can ensure that these

pumps are always in working order.

ALMATEC / ALLWEILER / ARO / APOLLO / ATURIA / AZCUE / BEHRENS / BORNEMANN / DANFOSS /

DESMI / EBARA / EUREKA / FRAMO / GARBARINO / GRUNDFOS / HEISHIN / JMW / IMO / IRON / KRAL /

KAWASAKI / NANIWA / PENTAX / RICKMEIER / SHINKO / SPECK / TAIKO KIKAI / WILO & many more

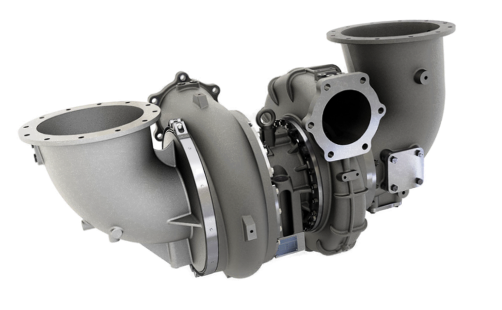

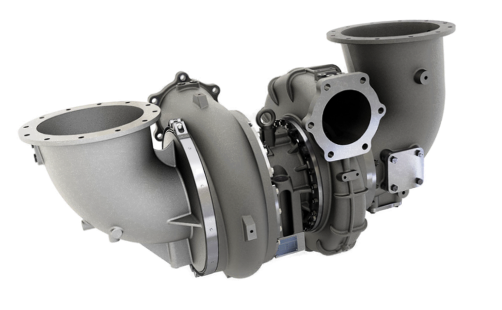

Turbo Charger

A turbocharger is an essential part of a marine engine. It reuses the exhaust gases and thus

increases the overall efficiency of the engine. These turbochargers consist of two main parts,

the blower side and the turbine side, which should be given special attention during

maintenance.

Increasing efficient energy within the turbocharger results in increased external power. This

energy is the driving force behind the engine and the movement of the vessel. Without an

efficiently working turbocharger, smooth engine performance is not possible.

As suppliers of marine turbocharger spare parts, we understand how important

turbochargers are to the operation of a vessel and therefore ensure that our services result in

the provision of high quality marine turbocharger spare parts. We have a wide range of newly

manufactured and fully refurbished replacement parts. By leveraging our knowledge and

experience in the OEM market, we can supply parts that are obsolete from the original

manufacturer.

ABB / I H I / KBB / MAN / MET / NAPIER / HOLSET

Sewage Treatment

Wastewater treatment is aimed at removing pollutants from wastewater to produce effluent that is

suitable for discharge into the environment or an intended reuse application, thereby preventing

water pollution from raw sewage discharge.

The Convention for the Prevention of Pollution from Ships (MARPOL) applies worldwide. According

to this convention, wastewater can be legally discharged into the sea beyond the 12 nautical mile

limit off the coast - treated wastewater that is close to drinking water quality can be discharged three

miles off the coast. However, stricter rules apply to particularly sensitive areas. In general,

wastewater is treated on board before discharge.

There are various technologies and methods of wastewater treatment on the market, such as

conventional biological activated sludge processes, compact membrane bioreactors (MBR) and

physical-chemical processes for projects with special requirements. The most common of these is

biological, as it takes up less space in the holding tank than the other methods. In addition, the

wastewater from this system is environmentally friendly. It should be noted that any wastewater

treatment system installed on board must be certified by a classification society and should comply

with the requirements and regulations of that society.

We understand the need and importance of wastewater treatment. Therefore, we ensure that our

customers' needs are met with the best and highest quality spare parts for the wastewater

treatment systems.

For the smooth operation of these plants, we supply spare parts of all major brands in the industry

through fast and cost-effective delivery to any location worldwide.

ACO / DETEGASA / DEYUAN / EVAC / GATHERING / HAMANN / HAMWORTHY / RWO / SASAKURA /

VICTOR

/ WÄRTSILÄ

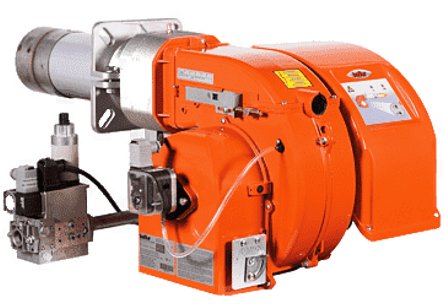

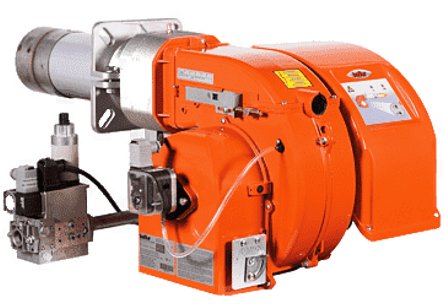

Incinerator & Burner

The incineration of liquid and solid waste is considered an environmentally friendly method of

waste disposal. On-board incineration with local disposal of sludge, oil and solid waste is

highly appreciated and recommended by the International Maritime Organization (IMO) and

all classification societies.

The purpose of a shipboard incinerator is to dispose of solid and/or sludge waste and other

materials generated on board in an environmentally friendly manner, while complying with

the latest IMO regulations.

For these plants, robust and compact high-performance burners are used not only for

incinerators but also for auxiliary and sanitary boilers, fuel supply and transportation of fuels

such as HFO, MDO, MGO, LPG, LNG.

As a long-standing partner of the marine industry, we supply a comprehensive range of

spare parts and complete units from burners and accessories to complete incinerators for all

marine applications with the corresponding classification approval.

ATLAS / BUDERUS / DETEGASA / FREMO / GHIERSCH / INTERCAL / SAACKE / SUNFLAME / SUNTEC /

TEAMTEC / WEISHAUPT

Blower

Ventilation systems for aeration and extraction within watertight areas or fire zones must be

designed as self-sufficient systems, and ventilation systems in potentially explosive

atmospheres require appropriate approval.

Fans are required almost everywhere on the ship, for air conditioning, heat recovery, heating,

cooling, ventilation or extraction systems.

Ventilation systems for ventilation and air conditioning of the various interior areas not only

provide comfortable working conditions for the crew and passengers, but also help to ensure

trouble-free operation for many other systems on board.

Fans and associated components for ships often work in continuous operation and must

meet special requirements and loads.

As a long-standing partner to the marine industry, we supply a comprehensive range of

spare parts and complete units from robust, efficient and low-maintenance fans to complete

ventilation systems for all marine applications with the corresponding classification approval.

ANTEWA / DLK / FIMA / EBM / ELT / GRONBACH / MORO / NICOTRA / NOLTE / STIAVELLI / TLT /

VENTI OELDE

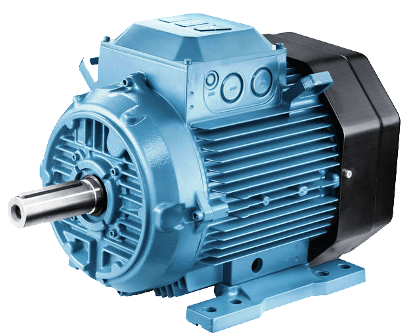

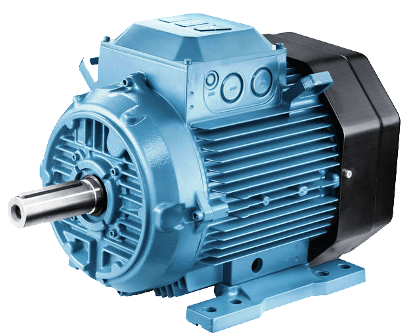

E-Motor

The on-board network for the electrical power supply on seagoing vessels is an island

network, which is usually fed by vessel diesel engine generators, shaft generators or, more

rarely, smaller turbo generators. Once the electrical energy has been generated, it is

distributed and used via a complex network of switchboards and cables.

Three-phase asynchronous machines have replaced steam or direct current machines as the

drive for auxiliary machines such as fans, pumps, air compressors, chillers and winches.

In cruise vessels and some other special vessels, the propellers are also driven by electric

motors. Extensive and powerful on-board power supply systems with outputs of up to 100

MW are used, which are fed by five to ten diesel generators.

As a rule, the on-board power supply is designed for a voltage of 440 V and a nominal

frequency of 60 Hz. Medium voltage 6.6 kV to 10 kV has advantages for outputs of 8 MW

and above and is used on passenger ships and large container ships with many refrigerated

containers. The installed electrical power of container ships in particular has increased

considerably over the last 20 years. On the one hand, ever larger ships of this type are being

built, so that the demand for electrical energy for normal ship operation alone has increased.

As a long-standing partner to the marine industry, we supply a comprehensive range of

electric motors and services for all marine applications with corresponding classification

approval.

We offer spare parts service and complete motors of all sizes and power ratings for pumps,

gearboxes, cranes, winches, gangways, elevators and many other systems.

ABB / AEG / HANSA / HOYER / KUENLE / MARELLI / MORATTI / OME / PALFINGER / RELIANCE /

SHIJIAZHUANG / SIEMENS / VEM

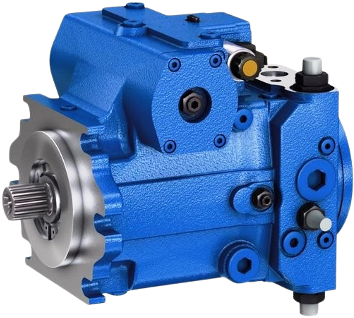

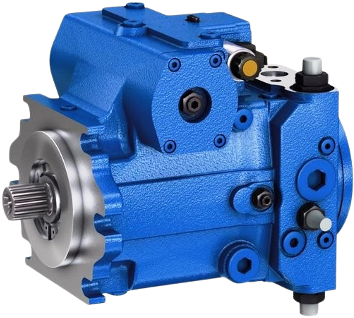

Pneumatics & Hydraulics

Fluid technology is the generic term for all processes in which energy is transferred by the flow of

gases and liquids. Fluid technology is used technically in hydraulics (transfer of energy through

hydraulic fluids) and pneumatics (transfer through compressed air). In both cases, energy is used to

generate movement.

A significant difference between the two fluid technologies is, for example, the use of gases or air in

pneumatics. These can be compressed and are therefore compressible, whereas a liquid used in

hydraulics is incompressible.

Marine pneumatics and hydraulics have developed into one of the most frequently used force and

torque delivery systems, primarily due to the highly efficient transmission of large linear and

rotational forces and torques. The areas of application are diverse:

Rotary and linear operation of cranes, control systems, remote-controlled- direct-controlled- and

servo-controlled valves, doors, ventilation flaps. Pressure switches for measuring and controlling the

pressure and temperature of air, gases and liquids. Rotary operation of winches, hydraulic bow and

stern thrusters, adjustable propellers. Rotary and linear operation of stabilizers, etc.

Pneumatics & hydraulics for the shipbuilding industry are used worldwide on a wide variety of ships

and in a wide variety of applications. They work at all times under the toughest conditions on the

high seas.

As a long-standing partner to the marine industry, we supply a comprehensive and flexible range of

products and services for all marine applications.We meet the special requirements with technically

mature products that have been developed to meet the high standards.

AVENTICS / CXPC / DANFOSS / FAG / FESTO / FESOLO / HAWE / HYDAC / INDUNORM / PARKER /

REXROTH

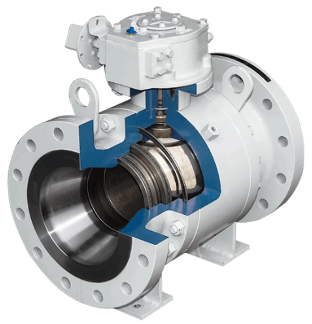

Fitting

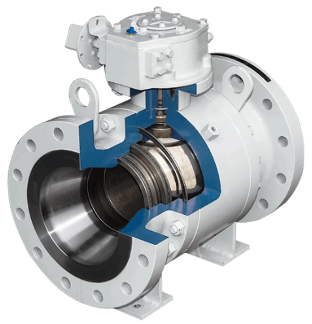

Valves in the shipbuilding industry are used on the high seas in a wide variety of complex

applications. It is important that the fittings can withstand the harsh conditions. You must

ensure security and availability in the processes on board at all times.

From cargo ships to LNG tankers and dredgers to passenger ships: valves for the

shipbuilding industry are used worldwide on a wide variety of ships and in a wide variety of

applications. These work at all times under the toughest conditions on the high seas.

As a long-standing partner to the marine industry, we deliver a comprehensive and flexible

range of products and services for all marine applications.

Thanks to the excellent quality, NIOTEC is the first choice as an official supplier for many

companies around the world. We meet the special requirements with technically

sophisticated products that have been developed to meet the high standards.

AEM / ARI / AUMA / AXFLOW / BÜRKERT / CLORIUS / DANFOSS / DECKMA / EBRO / EVAC / GESTRA

/

HELDEN / HERION / HYDAC / KSB / NORIS / PARKER / REXROTH / SCHLEY / STRAUB / TEMPRESS /

VIKING / WABKO / WIKA / WOLFF & many more